This page is as much a description of a layout as it is an expose and

review of the Fleischmann N-scale rack-rail system.

May it be useful to you.

This layout proved to require considerably more effort than I

anticipated, especially for a layout consisting of a single 50"

run of almost-straight track.

There was many a twist in that "almost".

The History

In the foreground you see the old benchtop from the Physics lab that was

renovated in Christmas 2006.

When Bruce and I saw these marvellous pieces of wood in the dumpster we

grabbed them. New Zealand Rimu,

at once I knew the stuff should be recycled in some beautiful and

exciting way. Back in California I had an idea for a wall-hangable layout

using the Fleischmann N-scale cog track and locomotive. Here was

just the material for this job: Beautiful wood that was thicker than an N-scale

layout needs to be wide.

In the foreground you see the old benchtop from the Physics lab that was

renovated in Christmas 2006.

When Bruce and I saw these marvellous pieces of wood in the dumpster we

grabbed them. New Zealand Rimu,

at once I knew the stuff should be recycled in some beautiful and

exciting way. Back in California I had an idea for a wall-hangable layout

using the Fleischmann N-scale cog track and locomotive. Here was

just the material for this job: Beautiful wood that was thicker than an N-scale

layout needs to be wide.

This is the woodwork part of the first version of the layout.

The route up the mountain is the edge of the frontmost

piece. The two routed recesses at either end will become

stations.

The idea is that the grainy Rimu wood represents rock,

the rock of a mountain, up the side of which a cog railway will

snake.

This is the woodwork part of the first version of the layout.

The route up the mountain is the edge of the frontmost

piece. The two routed recesses at either end will become

stations.

The idea is that the grainy Rimu wood represents rock,

the rock of a mountain, up the side of which a cog railway will

snake.

The layout was partly inspired by discovering the

rack railway system from my favourite N-scale maker, Fleischmann,

partly by the sight of the thick lab-bench wood,

and partly by a postcard that Dominique sent to us years ago.

This post card showed a number of European trains,

including the Pilatusbahn.

There are other cog railways such as one climbing Snowdonia in Wales

(http://www.snowdonrailway.co.uk/),

and Mount Washington in New Hampshire

(http://www.thecog.com/),

but the Pilatusbahn seems to be the epitomy.

There is a good potted history of cog rail at

http://www.cograilway.com/history.htm.

Note in the picture above the two electronic

signalling boxes, one at the entrance to each station,

are already built into the "rock". These are

GP2A25 Electro-optic proximity sensors for the automatic controller,

but they are about the size of a trackside signal when viewed in

N-scale.

The circular hole leads to a small control panel to activate the layout.

The layout is intended to be hung on a wall, just like a picture.

The train will periodically leave one station and climb or descend to the

other.

The Problems

I started writing this page in August 2007, as I tackled version 2 of the

layout.

Updates continue as I learn more about using the Fleischmann 87305, 9119 Rack Rail

and friends.

I am not sure if I will ever finish the layout, indeed I am sure it will never be

reliable enough to run without regular operator intention. Below is the

saga and the knowledge I have acquired about the whole N-scale funicular

system. It is a pity, as it looks awfully impressive.

Around February 2009, Fleischmann went into receivership and was bought by the

company that previously bought Roco and turned that company profitable.

The blogs intimate that it should have been no surprise, as their technology

had not matured as did other manufacturers, for example my brand new

loco pictured here is still a 3-pole design, and I gather all Fleischmann

locos remain so.

The Fleischmann cog system is supposed to be able to climb up to

a 30% grade grade. I dutifully designed the route with a maximum grade of

30% grade.

This is the Fleischmann 9119 Rack Rail.

Unlike the regular Fleischmann N-scale track, the rack rail

is not made with ballast formed into the plastic base

of the track, but resembles the common Peco flextrack and settrack

arrangement with individual sleepers (ties). It is the higher

profile type of track, and the rails do not like to deform when bent,

making it hard to manage.

This is the Fleischmann 9119 Rack Rail.

Unlike the regular Fleischmann N-scale track, the rack rail

is not made with ballast formed into the plastic base

of the track, but resembles the common Peco flextrack and settrack

arrangement with individual sleepers (ties). It is the higher

profile type of track, and the rails do not like to deform when bent,

making it hard to manage.

Note also the frequent holes placed to accomodate nails to hold the

track in place.

The sleepers are held together by the toothed rack in the middle

of the track. This protrudes above the rails and is engaged

by a cog on the axle of one pair of drive wheels in the

locomotive.

The sleepers are held together by the toothed rack in the middle

of the track. This protrudes above the rails and is engaged

by a cog on the axle of one pair of drive wheels in the

locomotive.

The first problem is that the rails have a tendency to buckle.

They bend around corners left and right just fine, but not in the other direction.

When trying to make them conform to the curvature of hills, they tend to spring

out of the plastic retainers on the sleepers/ties, damaging them.

The second problem is that the rail needs to be nailed in a lot of places,

for which it has numerous holes. However, when you have the nails in deep enough,

the rack is no longer flat, and it dips compared to the rails where the

nails are located.

The dips in the rack and the irregularity of the rails are not a problem,

except when you approach 30%, before which grade the slightest

imperfection leads to the cog letting go and the locomotive slithering

and juddering to a gruesome crash at the bottom of the hill.

The third problem concerns not the grade, but the rate at which

the track can transition from one grade to another.

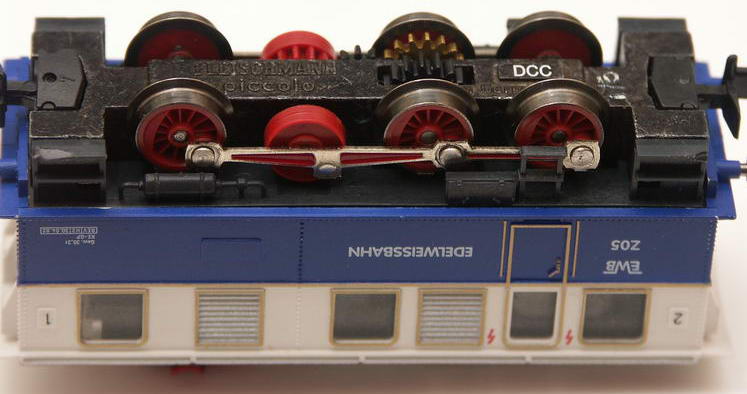

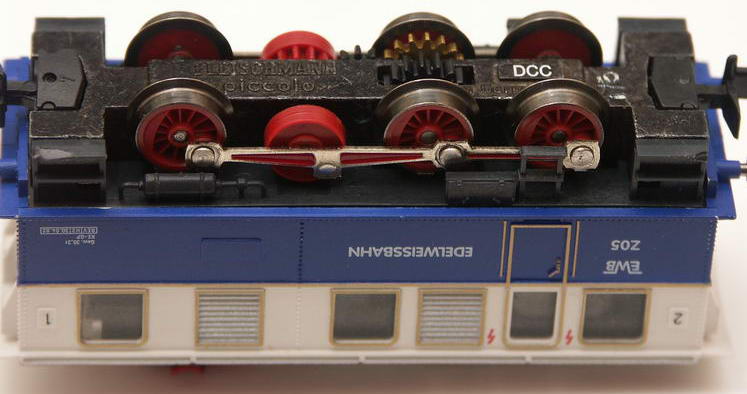

This is an underside view of the Fleischmann Edelweiss Cog Locomotive,

an 87305.

Note that it is a six-wheel arrangement, and that the cog that

engages the rack is on the middle of the three axles.

This is, I believe, a design flaw.

When the track curves in a convex fashion, there is a tendency to lift

one or both of the end axles off the rail, leaving the loco see-sawing.

Worse, a concave curvature lifts the axle with the cog, and the

loco is vastly more likely to let go and slide down.

It would function much better as a four-wheel design (perhaps like those

0-6-0 steam locomotives whose middle axle is largely cosmetic).

The third problem concerns not the grade, but the rate at which

the track can transition from one grade to another.

This is an underside view of the Fleischmann Edelweiss Cog Locomotive,

an 87305.

Note that it is a six-wheel arrangement, and that the cog that

engages the rack is on the middle of the three axles.

This is, I believe, a design flaw.

When the track curves in a convex fashion, there is a tendency to lift

one or both of the end axles off the rail, leaving the loco see-sawing.

Worse, a concave curvature lifts the axle with the cog, and the

loco is vastly more likely to let go and slide down.

It would function much better as a four-wheel design (perhaps like those

0-6-0 steam locomotives whose middle axle is largely cosmetic).

I was forced to rework the wood to reduce the radius of curvature

at both convex and concave locations. I scrapped much of the

track. I also devised a better method for attaching the

track to the wood base, dispensing with nails altogether.

The Second Version

This is the track half, viewed from the mountain side, after a rework

to reduce the radii of curvature. The most visible change is the use of

double-sided tape to mount the track. This proved to give much

less undulation in the rails.

This is the track half, viewed from the mountain side, after a rework

to reduce the radii of curvature. The most visible change is the use of

double-sided tape to mount the track. This proved to give much

less undulation in the rails.

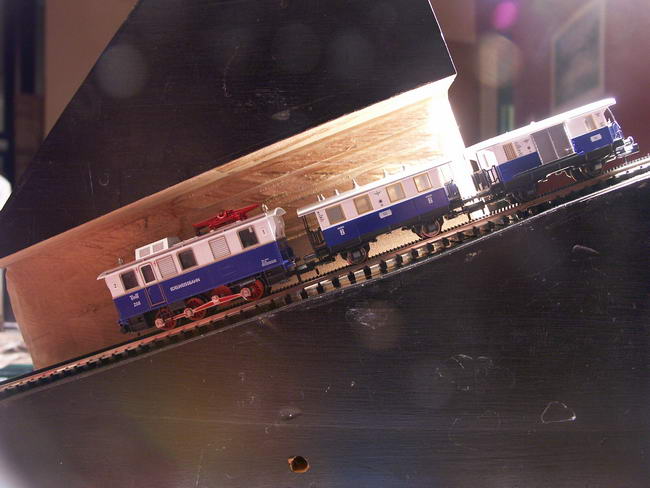

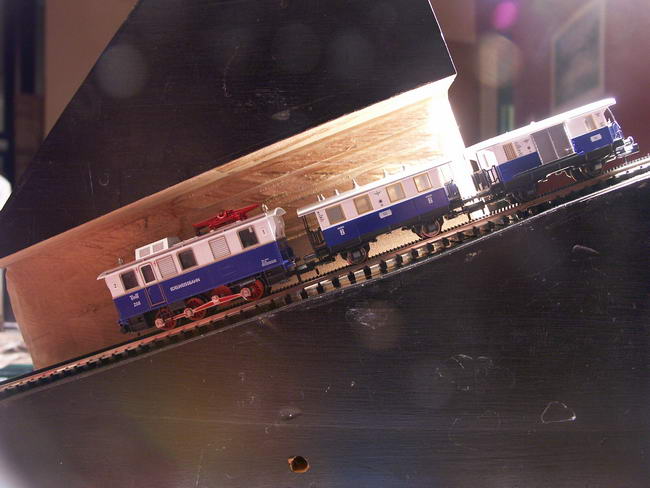

Just to give some idea of the steepness of the railway, this is a

picture taken with the camera horizontal. You are looking at the whole train

from within the cutaway mountain, and it is climbing out of the tunnel

towards the top station. The black faces mate with the other half of

the structure to complete the tunnel.

Just to give some idea of the steepness of the railway, this is a

picture taken with the camera horizontal. You are looking at the whole train

from within the cutaway mountain, and it is climbing out of the tunnel

towards the top station. The black faces mate with the other half of

the structure to complete the tunnel.

This closeup shows a section of track with a serious "bump"

in the near-side rail. The pins have been added to press the

bump down into the correct arc.

This may not seem like much, but it is enough to lift the

wheels on one side and stop the train. A concave, rather than convex,

bump, makes it let go and slide down.

This closeup shows a section of track with a serious "bump"

in the near-side rail. The pins have been added to press the

bump down into the correct arc.

This may not seem like much, but it is enough to lift the

wheels on one side and stop the train. A concave, rather than convex,

bump, makes it let go and slide down.

If you can see no error in the arc, compare the height

of the near-side rail with the height of the rack. In the

vicinity of the nail, note that the apparent height of the

teeth of the rack above the line of the top of the rail is

somewhat reduced. This undulation can barely be felt

by running your finger along the track quickly, while wearing

surgical gloves to reduce the sensation of roughness, but

it causes a perceptible roll in the motion of the loco.

Bending the rails absolutely demands a rail bender. The use of

a rail bender at such scales is virtually unheard-of, since

modern track flexes relatively easily in the X-Y plane,

but in the Y-Z plane it is another story altogether.

Bending the rails absolutely demands a rail bender. The use of

a rail bender at such scales is virtually unheard-of, since

modern track flexes relatively easily in the X-Y plane,

but in the Y-Z plane it is another story altogether.

Here is a rail bender fashioned from the bearings of an old

disk drive and some aluminium and steel plates and bolts.

Thanks to Brian Clark, workshop master. The

main plate is 45mm by 35mm.

Experience from Elsewhere

September 2009 saw me complete work on

Sprocket BahN,

another layout based on the same Fleischmann rack

rail system.

That layout is reasonably reliable, but will not run for days and days

without intervention, as one might hope for a layout that is fully

automated and expected to keep a timetable.

In the course of Sprocket BahN I hoped to sidestep all the problems

described above. I encountered yet another one: The cog meshing with

the rack converts force along the line of the track into a lifting force

that almost overpowers the weight from the steel masses in the

locomotive, resulting in the loco having greatly increased sensitivity

to small particles or discontinuities on the track. It regularly

loses electrical contact with one or other rail and "sticks".

On any given track there will be a speed setting that gives the loco

enough momentum to trundle over the discontinuities. The upshot

is that you have to run faster than you might like to make it

through the difficult parts, especially the concave regions

where the second derivative of height (the rate of change

of gradient) is largest.

--- there may be even more to come ---

The Layout Itself

Here are the Top and Bottom stations before the track is laid.

The buildings are from the Hornby Lyddle End range, but they have

been sawn to yield "relief" fronts (like something from

Portmeirion).

In the foreground you see the old benchtop from the Physics lab that was

renovated in Christmas 2006.

When Bruce and I saw these marvellous pieces of wood in the dumpster we

grabbed them. New Zealand Rimu,

at once I knew the stuff should be recycled in some beautiful and

exciting way. Back in California I had an idea for a wall-hangable layout

using the Fleischmann N-scale cog track and locomotive. Here was

just the material for this job: Beautiful wood that was thicker than an N-scale

layout needs to be wide.

In the foreground you see the old benchtop from the Physics lab that was

renovated in Christmas 2006.

When Bruce and I saw these marvellous pieces of wood in the dumpster we

grabbed them. New Zealand Rimu,

at once I knew the stuff should be recycled in some beautiful and

exciting way. Back in California I had an idea for a wall-hangable layout

using the Fleischmann N-scale cog track and locomotive. Here was

just the material for this job: Beautiful wood that was thicker than an N-scale

layout needs to be wide.

This is the woodwork part of the first version of the layout.

The route up the mountain is the edge of the frontmost

piece. The two routed recesses at either end will become

stations.

The idea is that the grainy Rimu wood represents rock,

the rock of a mountain, up the side of which a cog railway will

snake.

This is the woodwork part of the first version of the layout.

The route up the mountain is the edge of the frontmost

piece. The two routed recesses at either end will become

stations.

The idea is that the grainy Rimu wood represents rock,

the rock of a mountain, up the side of which a cog railway will

snake.

This is the Fleischmann 9119 Rack Rail.

Unlike the regular Fleischmann N-scale track, the rack rail

is not made with ballast formed into the plastic base

of the track, but resembles the common Peco flextrack and settrack

arrangement with individual sleepers (ties). It is the higher

profile type of track, and the rails do not like to deform when bent,

making it hard to manage.

This is the Fleischmann 9119 Rack Rail.

Unlike the regular Fleischmann N-scale track, the rack rail

is not made with ballast formed into the plastic base

of the track, but resembles the common Peco flextrack and settrack

arrangement with individual sleepers (ties). It is the higher

profile type of track, and the rails do not like to deform when bent,

making it hard to manage.

The sleepers are held together by the toothed rack in the middle

of the track. This protrudes above the rails and is engaged

by a cog on the axle of one pair of drive wheels in the

locomotive.

The sleepers are held together by the toothed rack in the middle

of the track. This protrudes above the rails and is engaged

by a cog on the axle of one pair of drive wheels in the

locomotive.

The third problem concerns not the grade, but the rate at which

the track can transition from one grade to another.

This is an underside view of the Fleischmann Edelweiss Cog Locomotive,

an 87305.

Note that it is a six-wheel arrangement, and that the cog that

engages the rack is on the middle of the three axles.

This is, I believe, a design flaw.

When the track curves in a convex fashion, there is a tendency to lift

one or both of the end axles off the rail, leaving the loco see-sawing.

Worse, a concave curvature lifts the axle with the cog, and the

loco is vastly more likely to let go and slide down.

It would function much better as a four-wheel design (perhaps like those

0-6-0 steam locomotives whose middle axle is largely cosmetic).

The third problem concerns not the grade, but the rate at which

the track can transition from one grade to another.

This is an underside view of the Fleischmann Edelweiss Cog Locomotive,

an 87305.

Note that it is a six-wheel arrangement, and that the cog that

engages the rack is on the middle of the three axles.

This is, I believe, a design flaw.

When the track curves in a convex fashion, there is a tendency to lift

one or both of the end axles off the rail, leaving the loco see-sawing.

Worse, a concave curvature lifts the axle with the cog, and the

loco is vastly more likely to let go and slide down.

It would function much better as a four-wheel design (perhaps like those

0-6-0 steam locomotives whose middle axle is largely cosmetic).

This is the track half, viewed from the mountain side, after a rework

to reduce the radii of curvature. The most visible change is the use of

double-sided tape to mount the track. This proved to give much

less undulation in the rails.

This is the track half, viewed from the mountain side, after a rework

to reduce the radii of curvature. The most visible change is the use of

double-sided tape to mount the track. This proved to give much

less undulation in the rails.

Just to give some idea of the steepness of the railway, this is a

picture taken with the camera horizontal. You are looking at the whole train

from within the cutaway mountain, and it is climbing out of the tunnel

towards the top station. The black faces mate with the other half of

the structure to complete the tunnel.

Just to give some idea of the steepness of the railway, this is a

picture taken with the camera horizontal. You are looking at the whole train

from within the cutaway mountain, and it is climbing out of the tunnel

towards the top station. The black faces mate with the other half of

the structure to complete the tunnel.

This closeup shows a section of track with a serious "bump"

in the near-side rail. The pins have been added to press the

bump down into the correct arc.

This may not seem like much, but it is enough to lift the

wheels on one side and stop the train. A concave, rather than convex,

bump, makes it let go and slide down.

This closeup shows a section of track with a serious "bump"

in the near-side rail. The pins have been added to press the

bump down into the correct arc.

This may not seem like much, but it is enough to lift the

wheels on one side and stop the train. A concave, rather than convex,

bump, makes it let go and slide down.

Bending the rails absolutely demands a rail bender. The use of

a rail bender at such scales is virtually unheard-of, since

modern track flexes relatively easily in the X-Y plane,

but in the Y-Z plane it is another story altogether.

Bending the rails absolutely demands a rail bender. The use of

a rail bender at such scales is virtually unheard-of, since

modern track flexes relatively easily in the X-Y plane,

but in the Y-Z plane it is another story altogether.